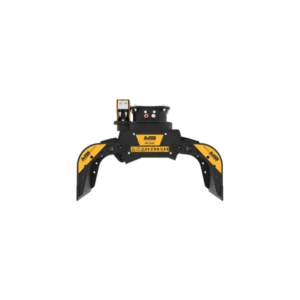

MB-G400 S4 Sorting Grapple

MB-G400 S4 Sorting Grapple – compact and precise grapple for 2.4–4 ton mini excavators. Ideal for lifting, sorting, and precise material placement with 360° hydraulic rotation.

MB-G400 S4 – Compact Sorting Grapple with Rotation for Mini Excavators

The MB-G400 S4 Sorting Grapple is engineered for mini excavators from 2.4 to 4 tons and is designed to simplify tasks across construction, landscaping, and agricultural job sites. This compact, lightweight, and versatile attachment handles logs, rocks, debris, brushwood, and large stones with precision and safety.

The grapple features a wide jaw opening for efficient handling of bulky materials and includes a load-holding valve for safe lifting operations. It is equipped with a silent block system to reduce noise levels—ideal for urban and residential work environments. Wear parts are made from Hardox® steel for extended durability, and the interchangeable blades can be flipped to prolong service life.

The MB-G400 S4 supports installation of an electrical kit to allow 360° continuous rotation even on excavators with only two hydraulic lines. Available in two models—with or without a rotating turret—this unit adapts perfectly to different operator needs and machine setups.

| Specification | Value (Metric) |

|---|---|

| Recommended Excavator | 2,400 – 4,000 kg |

| Rotation | 360° Hydraulic |

| Hydraulic Pressure (Rotation) | 130 – 170 bar |

| Oil Flow Rate (Rotation) | 7 – 11 L/min |

| Hydraulic Pressure (Open/Close) | 180 – 220 bar |

| Oil Flow Rate (Open/Close) | 19 – 26 L/min |

Optimized for 2.4–4 Ton Mini Excavators

Lightweight and efficient, this grapple is perfect for smaller machines and compact job sites where precision is key.360° Rotation with Optional 2-Hose Kit

Supports continuous hydraulic rotation, even with machines that have limited hydraulic lines, via an optional electrical kit.Hardox®-Reinforced & Reversible Blades

Wear components are built with ultra-tough Hardox steel, and blades can be flipped to extend operating life and reduce maintenance costs.Silent Operation with Safety Valve

Equipped with a silent block to reduce jobsite noise and a load-holding valve for secure material handling. MB-G400 S4 Sorting Grapple

MB-G400 S4 Sorting Grapple

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

MB-G400 S4 – Compact Sorting Grapple with Rotation for Mini Excavators

The MB-G400 S4 Sorting Grapple is engineered for mini excavators from 2.4 to 4 tons and is designed to simplify tasks across construction, landscaping, and agricultural job sites. This compact, lightweight, and versatile attachment handles logs, rocks, debris, brushwood, and large stones with precision and safety.

The grapple features a wide jaw opening for efficient handling of bulky materials and includes a load-holding valve for safe lifting operations. It is equipped with a silent block system to reduce noise levels—ideal for urban and residential work environments. Wear parts are made from Hardox® steel for extended durability, and the interchangeable blades can be flipped to prolong service life.

The MB-G400 S4 supports installation of an electrical kit to allow 360° continuous rotation even on excavators with only two hydraulic lines. Available in two models—with or without a rotating turret—this unit adapts perfectly to different operator needs and machine setups.

| Specification | Value (Metric) |

|---|---|

| Recommended Excavator | 2,400 – 4,000 kg |

| Rotation | 360° Hydraulic |

| Hydraulic Pressure (Rotation) | 130 – 170 bar |

| Oil Flow Rate (Rotation) | 7 – 11 L/min |

| Hydraulic Pressure (Open/Close) | 180 – 220 bar |

| Oil Flow Rate (Open/Close) | 19 – 26 L/min |

Optimized for 2.4–4 Ton Mini Excavators

Lightweight and efficient, this grapple is perfect for smaller machines and compact job sites where precision is key.360° Rotation with Optional 2-Hose Kit

Supports continuous hydraulic rotation, even with machines that have limited hydraulic lines, via an optional electrical kit.Hardox®-Reinforced & Reversible Blades

Wear components are built with ultra-tough Hardox steel, and blades can be flipped to extend operating life and reduce maintenance costs.Silent Operation with Safety Valve

Equipped with a silent block to reduce jobsite noise and a load-holding valve for secure material handling. MB-G400 S4 Sorting Grapple

MB-G400 S4 Sorting Grapple

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections