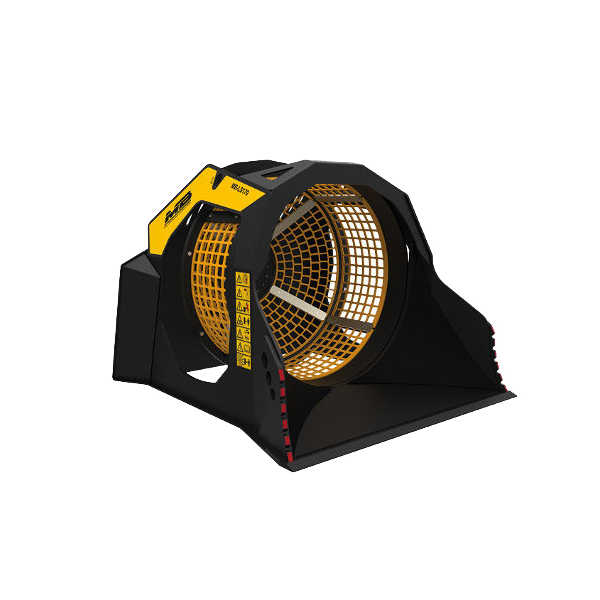

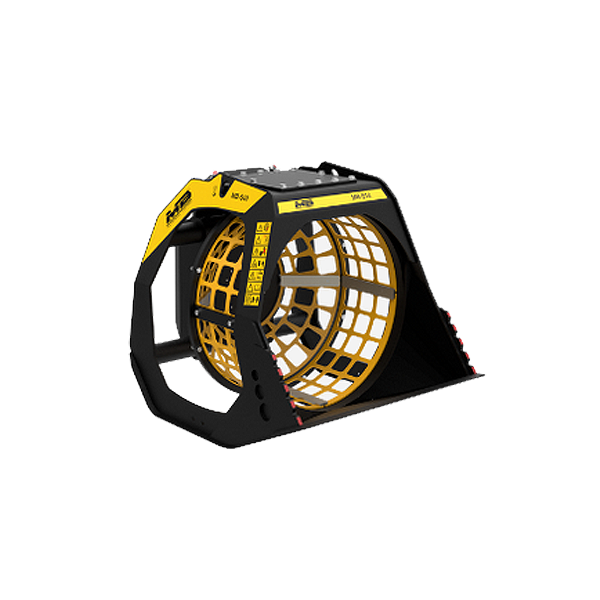

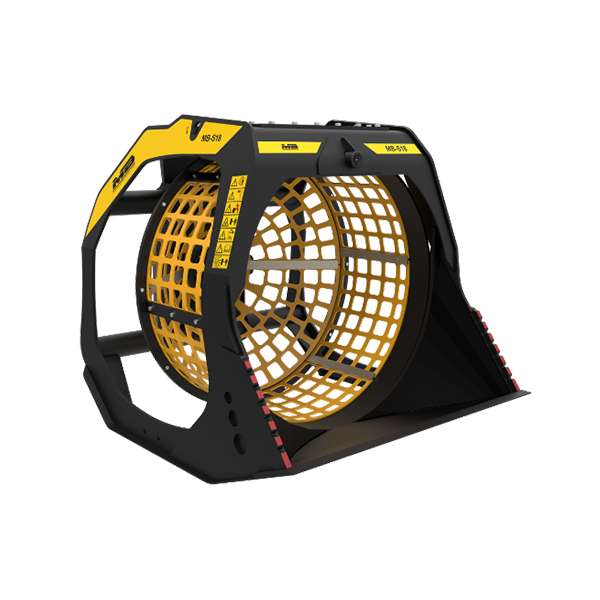

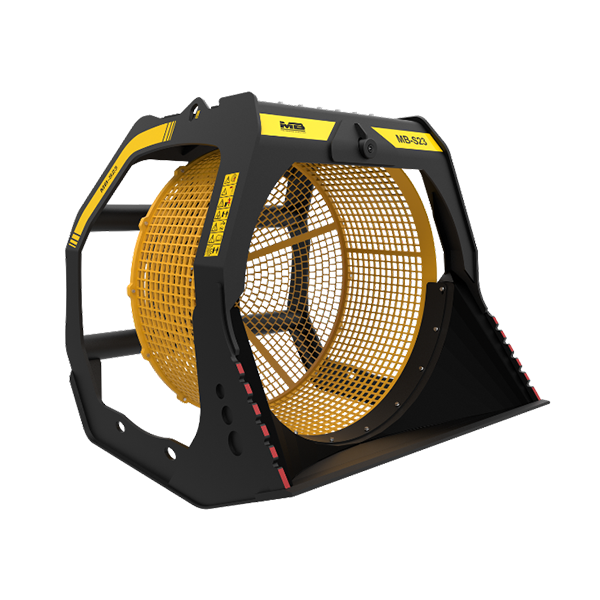

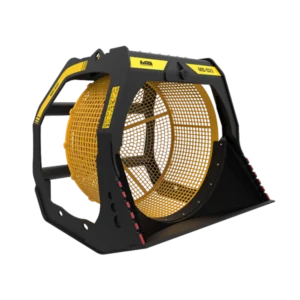

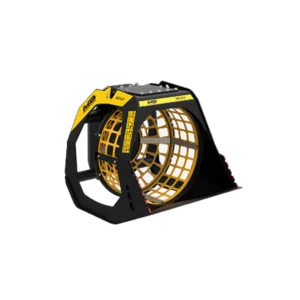

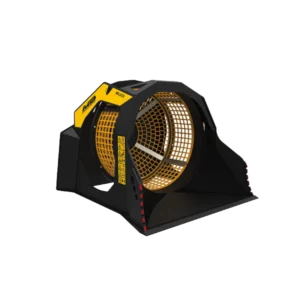

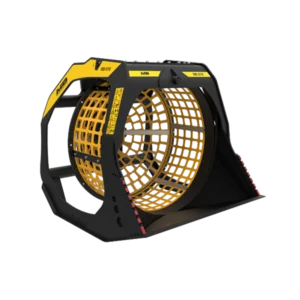

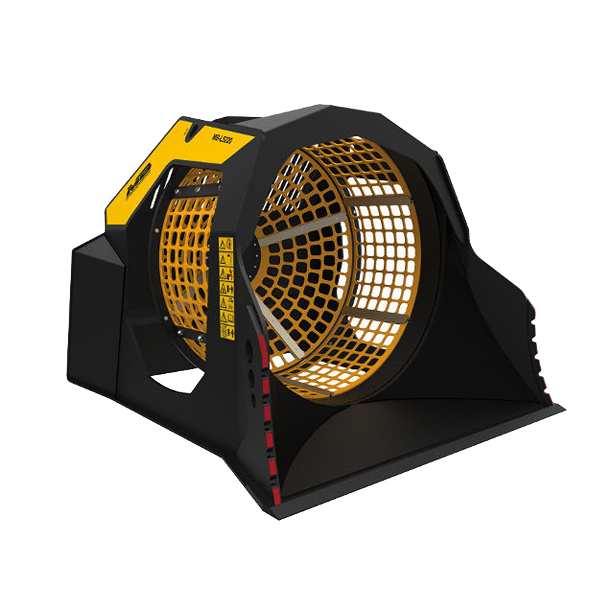

MB-LS220 S2 Screening Bucket

MB-LS220 S2 Screening Bucket – high-capacity screening bucket for large loaders. Ideal for natural material selection in quarries and bulk processing sites.

MB Crusher MB-LS220 S2 – Screening Bucket for Loaders (Heavy-Duty Material Sorting)

The MB-LS220 S2 screening bucket is the largest in the MB range for loaders and backhoes. Built for large-scale operations in quarries and processing yards, it streamlines material sorting and reduces crushing time by up to 60%.

Designed for loaders from 15,000 – 25,000 kg, this bucket features a massive 2.4 m³ load capacity and supports pre- and post-crushing stages. Its modular sieve panels allow for quick changes to output size based on job requirements.

With fast installation and interchangeable screen panels, the MB-LS220 S2 increases efficiency on any project involving earthmoving, mining, landscaping, or bulk material screening. Ensure your loader meets the necessary hydraulic flow and pressure for optimal use.

| Specification | Value (Metric) |

|---|---|

| Recommended Loader | 15,000 – 25,000 kg |

| Load Capacity | 2.4 m³ |

| Hydraulic Pressure | 200 – 250 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 120 – 140 L/min |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

BUILT FOR HIGH-VOLUME SORTING

With a 2.4 m³ load capacity, the MB-LS220 S2 is perfect for screening large volumes of material in quarries, mining operations, and large yards.MODULAR SCREEN PANELS

Interchangeable sieve panels allow operators to quickly switch between different material sizes, saving time and increasing flexibility on the job site.IDEAL FOR PRE- AND POST-CRUSHING

Use this screening bucket to remove unwanted material before crushing or recover valuable product afterward—reducing total crushing time by up to 60%.MB-ENGINEERED EFFICIENCY

Made in Italy with top-grade components, the LS220 delivers long-term performance with minimal maintenance requirements even in tough conditions. MB-LS220 S2 Screening Bucket

MB-LS220 S2 Screening Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

MB Crusher MB-LS220 S2 – Screening Bucket for Loaders (Heavy-Duty Material Sorting)

The MB-LS220 S2 screening bucket is the largest in the MB range for loaders and backhoes. Built for large-scale operations in quarries and processing yards, it streamlines material sorting and reduces crushing time by up to 60%.

Designed for loaders from 15,000 – 25,000 kg, this bucket features a massive 2.4 m³ load capacity and supports pre- and post-crushing stages. Its modular sieve panels allow for quick changes to output size based on job requirements.

With fast installation and interchangeable screen panels, the MB-LS220 S2 increases efficiency on any project involving earthmoving, mining, landscaping, or bulk material screening. Ensure your loader meets the necessary hydraulic flow and pressure for optimal use.

| Specification | Value (Metric) |

|---|---|

| Recommended Loader | 15,000 – 25,000 kg |

| Load Capacity | 2.4 m³ |

| Hydraulic Pressure | 200 – 250 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 120 – 140 L/min |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

BUILT FOR HIGH-VOLUME SORTING

With a 2.4 m³ load capacity, the MB-LS220 S2 is perfect for screening large volumes of material in quarries, mining operations, and large yards.MODULAR SCREEN PANELS

Interchangeable sieve panels allow operators to quickly switch between different material sizes, saving time and increasing flexibility on the job site.IDEAL FOR PRE- AND POST-CRUSHING

Use this screening bucket to remove unwanted material before crushing or recover valuable product afterward—reducing total crushing time by up to 60%.MB-ENGINEERED EFFICIENCY

Made in Italy with top-grade components, the LS220 delivers long-term performance with minimal maintenance requirements even in tough conditions. MB-LS220 S2 Screening Bucket

MB-LS220 S2 Screening Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections