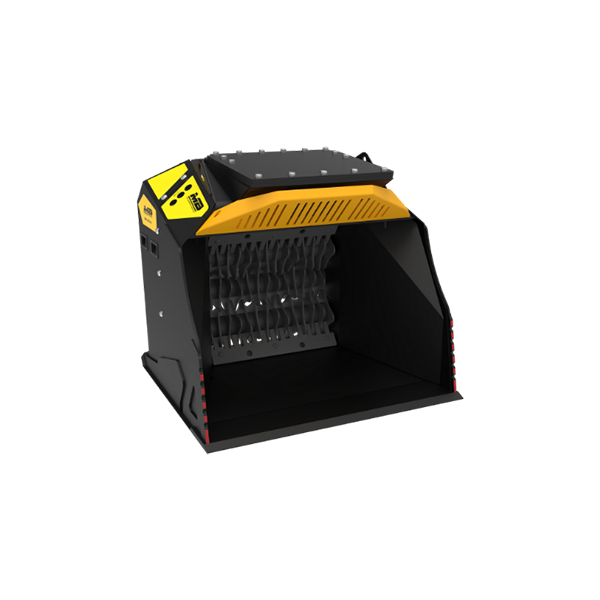

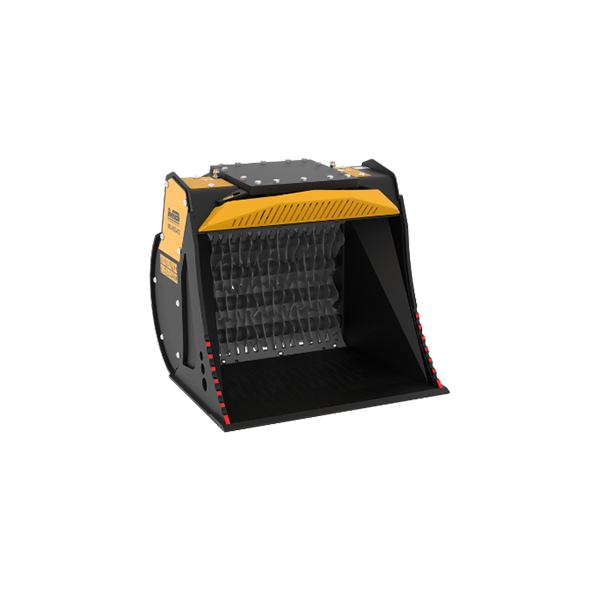

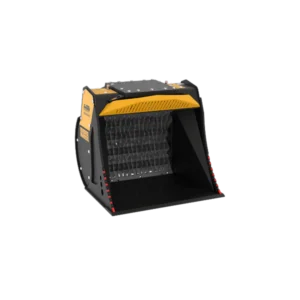

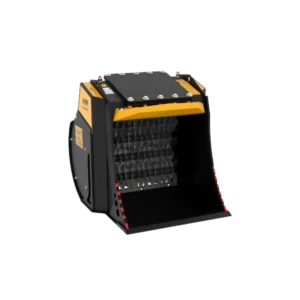

MB-HDS320 Padding Bucket

MB-HDS320 Padding Bucket – a large-capacity shaft screener for excavators and loaders. Built to process demolition debris, asphalt, wood, plastics, and more—directly on-site.

MB Crusher MB-HDS320 – Heavy-Duty Screening Bucket for Excavators & Loaders

The MB-HDS320 shaft screening bucket is the most advanced and adaptable solution in the MB Crusher range for large excavators and loaders. Built for excavators from 18 – 25 tons and loaders from 11 – 14 tons, this unit is engineered to crush and separate a wide range of materials directly on-site—without needing multiple tools.

With an impressive 1.35 m³ load capacity, the MB-HDS320 can handle excavation waste, asphalt, organic matter, bark, plastics, and even coal. The true innovation lies in the rotor-change system—rotating shafts can be swapped out on site in just minutes by a single operator, improving versatility and efficiency.

Built with safety, simplicity, and productivity in mind, this screener bucket minimizes downtime and transforms waste into reusable, profitable material. MB’s centralized greasing system and modular build make this one of the most profitable attachments in the field.

| Specification | Value (Metric) |

|---|---|

| Recommended Excavator | 18,000 – 25,000 kg |

| Recommended Loader | 11,000 – 14,000 kg |

| Load Capacity | 1.35 m³ |

| Hydraulic Pressure | 250 – 300 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 120 – 160 L/min |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

HEAVY-DUTY SCREENING FOR 18–25T EXCAVATORS

Purpose-built for large-scale jobs, demolition cleanup, and waste transformation across construction, coal, and recycling sectors.UNMATCHED MATERIAL VERSATILITY

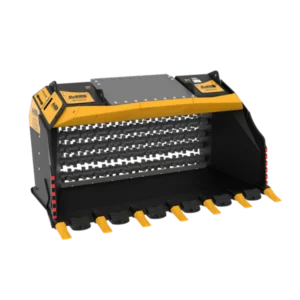

Processes wood, bark, plastics, coal, organic waste, asphalt, and debris—all with one machine using interchangeable rotors.FAST SHAFT REPLACEMENT SYSTEM

Change rotating shafts in minutes—on-site and without special tools—ensuring unmatched flexibility and minimum downtime.DESIGNED FOR MAXIMUM PRODUCTIVITY

Robust MB construction, wide mouth opening, and centralized greasing ensure peak performance with minimal maintenance. MB-HDS320 Padding Bucket

MB-HDS320 Padding Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

MB Crusher MB-HDS320 – Heavy-Duty Screening Bucket for Excavators & Loaders

The MB-HDS320 shaft screening bucket is the most advanced and adaptable solution in the MB Crusher range for large excavators and loaders. Built for excavators from 18 – 25 tons and loaders from 11 – 14 tons, this unit is engineered to crush and separate a wide range of materials directly on-site—without needing multiple tools.

With an impressive 1.35 m³ load capacity, the MB-HDS320 can handle excavation waste, asphalt, organic matter, bark, plastics, and even coal. The true innovation lies in the rotor-change system—rotating shafts can be swapped out on site in just minutes by a single operator, improving versatility and efficiency.

Built with safety, simplicity, and productivity in mind, this screener bucket minimizes downtime and transforms waste into reusable, profitable material. MB’s centralized greasing system and modular build make this one of the most profitable attachments in the field.

| Specification | Value (Metric) |

|---|---|

| Recommended Excavator | 18,000 – 25,000 kg |

| Recommended Loader | 11,000 – 14,000 kg |

| Load Capacity | 1.35 m³ |

| Hydraulic Pressure | 250 – 300 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 120 – 160 L/min |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

HEAVY-DUTY SCREENING FOR 18–25T EXCAVATORS

Purpose-built for large-scale jobs, demolition cleanup, and waste transformation across construction, coal, and recycling sectors.UNMATCHED MATERIAL VERSATILITY

Processes wood, bark, plastics, coal, organic waste, asphalt, and debris—all with one machine using interchangeable rotors.FAST SHAFT REPLACEMENT SYSTEM

Change rotating shafts in minutes—on-site and without special tools—ensuring unmatched flexibility and minimum downtime.DESIGNED FOR MAXIMUM PRODUCTIVITY

Robust MB construction, wide mouth opening, and centralized greasing ensure peak performance with minimal maintenance. MB-HDS320 Padding Bucket

MB-HDS320 Padding Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections