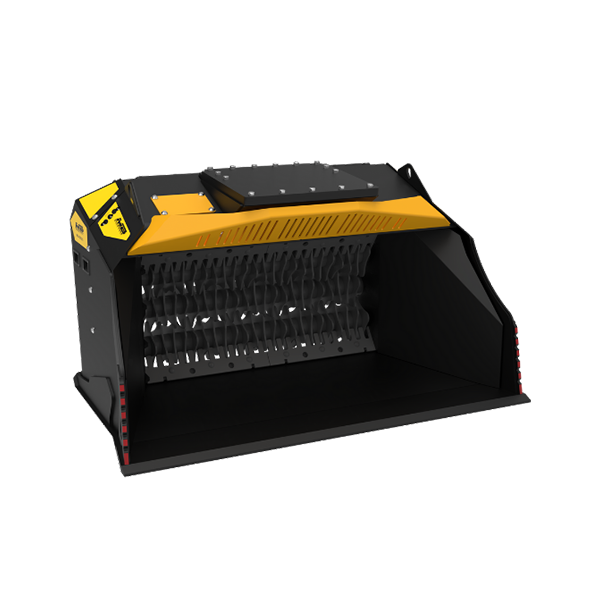

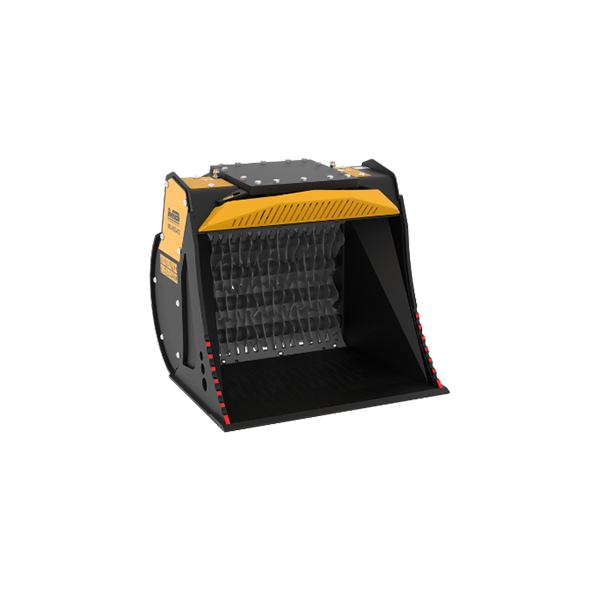

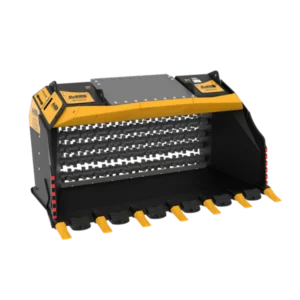

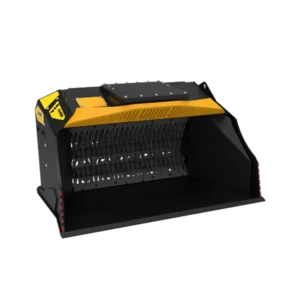

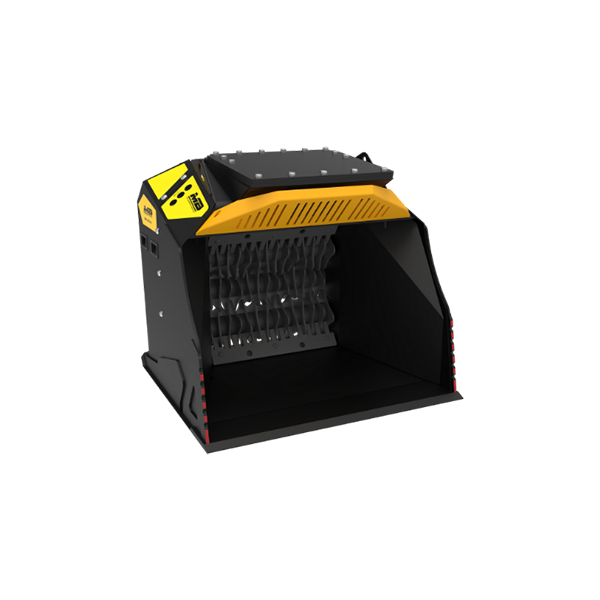

MB-HDS314 Padding Bucket

MB-HDS314 Padding Bucket – heavy-duty shaft screener for excavators and loaders. Designed to transform site waste into valuable, reusable material with speed and precision.

MB Crusher MB-HDS314 – Large-Capacity Padding Bucket for Excavators & Loaders

The MB-HDS314 shaft screening bucket is the ideal solution for job sites focused on recycling and resource efficiency. Designed for excavators from 13 – 20 tons and loaders from 9 – 14 tons, this screener transforms construction waste into valuable, reusable material on-site.

With an impressive 0.9 m³ load capacity, the MB-HDS314 is engineered to handle a wide range of materials—from topsoil and gravel to demolition debris and construction waste. Its unique shaft system and robust design allow operators to adapt quickly to changing job site demands.

Like other MB HDS models, the MB-HDS314 features easy rotor replacement directly on-site, centralized greasing, and exceptional maneuverability. It is a practical and profitable asset for construction, earthmoving, and material processing operations.

| Specification | Value (Metric) |

|---|---|

| Recommended Excavator | 13,000 – 20,000 kg |

| Recommended Loader | 9,000 – 14,000 kg |

| Load Capacity | 0.9 m³ |

| Hydraulic Pressure | 230 – 280 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 100 – 160 L/min |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

ENGINEERED FOR 13–20T EXCAVATORS & LARGE LOADERS

Designed to handle heavy-duty screening tasks on construction, recycling, and earthworks projects using powerful mid- to large-sized machines.MULTI-MATERIAL COMPATIBILITY

Processes topsoil, gravel, rubble, and other mixed debris with precision and efficiency to produce reusable, clean material.ON-SITE SHAFT REPLACEMENT

Adapt quickly to different screening tasks with MB’s easy rotor swap system—no downtime, no specialist tools required.MAXIMIZES JOBSITE PROFITABILITY

Designed to reduce transport and disposal costs by repurposing waste into usable construction material right on-site. MB-HDS314 Padding Bucket

MB-HDS314 Padding Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

MB Crusher MB-HDS314 – Large-Capacity Padding Bucket for Excavators & Loaders

The MB-HDS314 shaft screening bucket is the ideal solution for job sites focused on recycling and resource efficiency. Designed for excavators from 13 – 20 tons and loaders from 9 – 14 tons, this screener transforms construction waste into valuable, reusable material on-site.

With an impressive 0.9 m³ load capacity, the MB-HDS314 is engineered to handle a wide range of materials—from topsoil and gravel to demolition debris and construction waste. Its unique shaft system and robust design allow operators to adapt quickly to changing job site demands.

Like other MB HDS models, the MB-HDS314 features easy rotor replacement directly on-site, centralized greasing, and exceptional maneuverability. It is a practical and profitable asset for construction, earthmoving, and material processing operations.

| Specification | Value (Metric) |

|---|---|

| Recommended Excavator | 13,000 – 20,000 kg |

| Recommended Loader | 9,000 – 14,000 kg |

| Load Capacity | 0.9 m³ |

| Hydraulic Pressure | 230 – 280 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 100 – 160 L/min |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

ENGINEERED FOR 13–20T EXCAVATORS & LARGE LOADERS

Designed to handle heavy-duty screening tasks on construction, recycling, and earthworks projects using powerful mid- to large-sized machines.MULTI-MATERIAL COMPATIBILITY

Processes topsoil, gravel, rubble, and other mixed debris with precision and efficiency to produce reusable, clean material.ON-SITE SHAFT REPLACEMENT

Adapt quickly to different screening tasks with MB’s easy rotor swap system—no downtime, no specialist tools required.MAXIMIZES JOBSITE PROFITABILITY

Designed to reduce transport and disposal costs by repurposing waste into usable construction material right on-site. MB-HDS314 Padding Bucket

MB-HDS314 Padding Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections