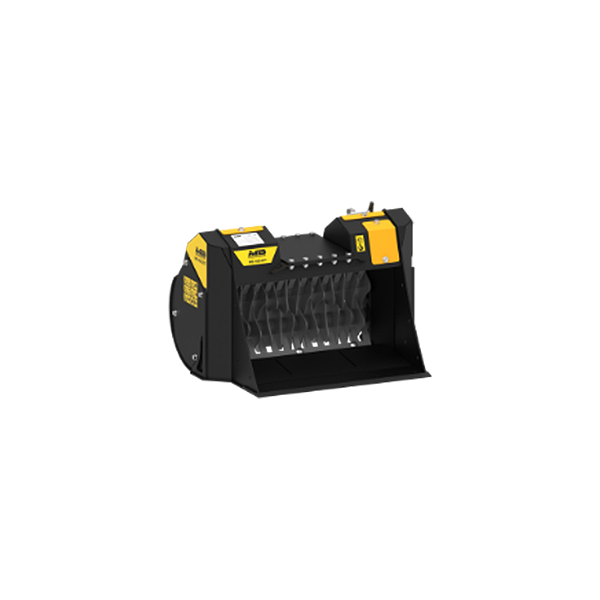

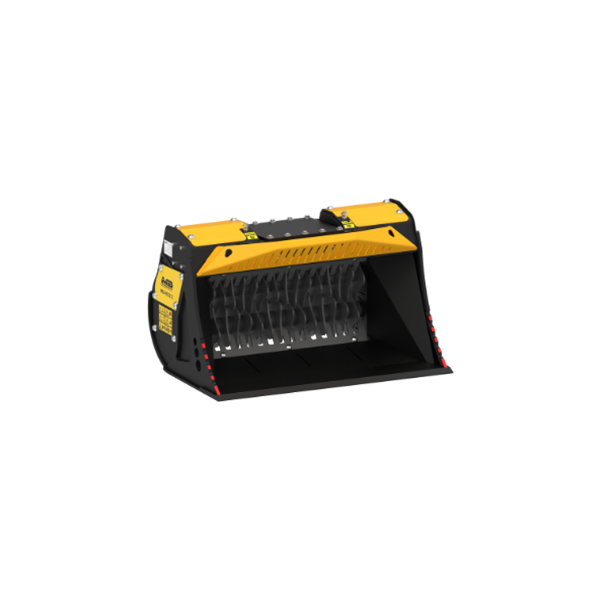

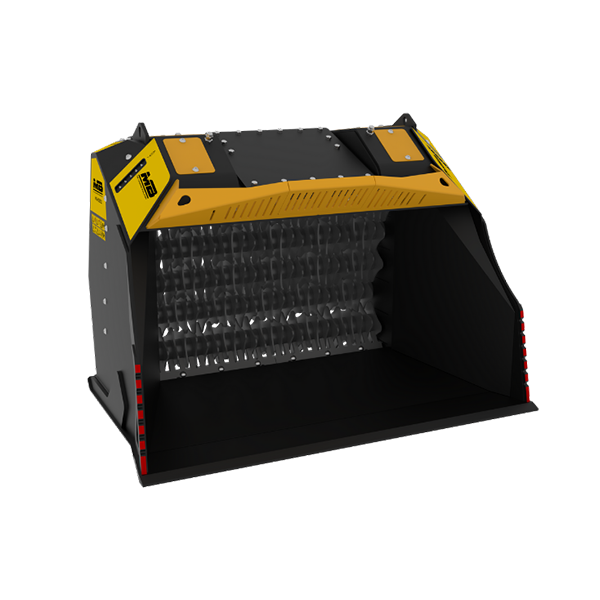

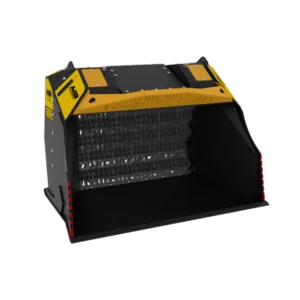

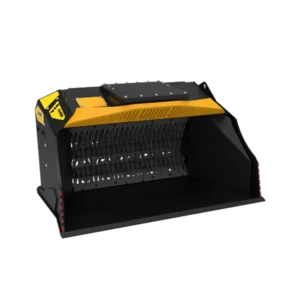

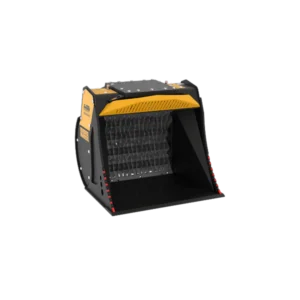

MB-HDS220 Padding Bucket

MB-HDS220 Padding Bucket – high-capacity shaft screener for loaders, backhoes, and skid steers. Built for efficiency, fast rotor changes, and reduced processing costs on-site.

MB Crusher MB-HDS220 – Heavy-Duty Padding Bucket for Loaders & Skid Steers

The MB-HDS220 shaft screening bucket is designed for unmatched productivity in construction, recycling, and landscaping. Suitable for skid steers and loaders from 4.5 – 10 tons, and backhoe loaders up to 11 tons, this model was unveiled at Conexpo 2023 as the go-to tool for serious on-site efficiency.

With a 0.6 m³ load capacity and a total weight of 1,000 kg, the MB-HDS220 stands out for its 2,200 mm wide inlet mouth, allowing easy loading without soiling the carrier’s wheels or tracks. The streamlined design quickly channels material to the rotors, ensuring excellent throughput even with dense or wet material.

Like all MB Crusher HDS units, the MB-HDS220 features quick rotor changeability, centralized greasing, and robust construction. Its coupling system offers unmatched visibility and maneuverability, reducing downtime and increasing site safety and precision.

| Specification | Value (Metric) |

|---|---|

| Recommended Backhoe Loader | 7,000 – 11,000 kg |

| Recommended Skid Steer Loader | 4,500 – 10,000 kg |

| Load Capacity | 0.6 m³ |

| Machine Width / Mouth Opening | 2,200 mm |

| Hydraulic Pressure | 230 – 280 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 90 – 265 L/min |

| Backhoe Compatibility Note | Only compatible with the posterior boom of a backhoe. |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

EXCEPTIONAL CAPACITY FOR SKID STEERS & LOADERS

With a 0.6 m³ load capacity and 2,200 mm wide inlet, this unit enables faster loading and screening without soiling the carrier machine.QUICK ROTOR REPLACEMENT

Rotors can be swapped directly on-site without specialized tools—ideal for contractors working with different material types.MAXIMUM VISIBILITY & CONTROL

The coupler and frame design offer excellent operator visibility, safer handling, and better control over screened materials.MADE FOR JOBSITE EFFICIENCY

Centralized greasing, streamlined design, and maneuverable build reduce downtime and speed up project turnaround. MB-HDS220 Padding Bucket

MB-HDS220 Padding Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections

MB Crusher MB-HDS220 – Heavy-Duty Padding Bucket for Loaders & Skid Steers

The MB-HDS220 shaft screening bucket is designed for unmatched productivity in construction, recycling, and landscaping. Suitable for skid steers and loaders from 4.5 – 10 tons, and backhoe loaders up to 11 tons, this model was unveiled at Conexpo 2023 as the go-to tool for serious on-site efficiency.

With a 0.6 m³ load capacity and a total weight of 1,000 kg, the MB-HDS220 stands out for its 2,200 mm wide inlet mouth, allowing easy loading without soiling the carrier’s wheels or tracks. The streamlined design quickly channels material to the rotors, ensuring excellent throughput even with dense or wet material.

Like all MB Crusher HDS units, the MB-HDS220 features quick rotor changeability, centralized greasing, and robust construction. Its coupling system offers unmatched visibility and maneuverability, reducing downtime and increasing site safety and precision.

| Specification | Value (Metric) |

|---|---|

| Recommended Backhoe Loader | 7,000 – 11,000 kg |

| Recommended Skid Steer Loader | 4,500 – 10,000 kg |

| Load Capacity | 0.6 m³ |

| Machine Width / Mouth Opening | 2,200 mm |

| Hydraulic Pressure | 230 – 280 bar |

| Back Pressure | < 20 bar |

| Oil Flow Rate | 90 – 265 L/min |

| Backhoe Compatibility Note | Only compatible with the posterior boom of a backhoe. |

| Hydraulic Requirement Note | Hydraulic flow and pressure must meet required parameters. |

EXCEPTIONAL CAPACITY FOR SKID STEERS & LOADERS

With a 0.6 m³ load capacity and 2,200 mm wide inlet, this unit enables faster loading and screening without soiling the carrier machine.QUICK ROTOR REPLACEMENT

Rotors can be swapped directly on-site without specialized tools—ideal for contractors working with different material types.MAXIMUM VISIBILITY & CONTROL

The coupler and frame design offer excellent operator visibility, safer handling, and better control over screened materials.MADE FOR JOBSITE EFFICIENCY

Centralized greasing, streamlined design, and maneuverable build reduce downtime and speed up project turnaround. MB-HDS220 Padding Bucket

MB-HDS220 Padding Bucket

| 5 star | 0% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Sorry, no reviews match your current selections